9 tips to work properly in the EPAs

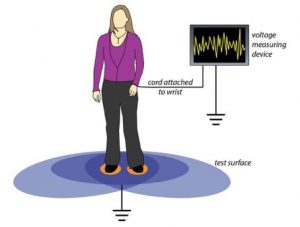

In previous articles we understood the importance of the tools that must be used in controlled static electricity areas. But what other precautions must be taken when working in EPAs?

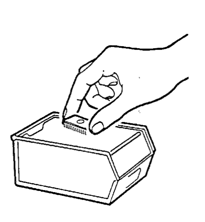

1. It is important to collect defective components in protective containers that are removed after repair

The components diagnosed as faulty and removed from the groups must be treated with the same care and precautions as the functioning components. Only in this way, avoiding further damages, the analysis of the failures that may be carried out will be meaningful.

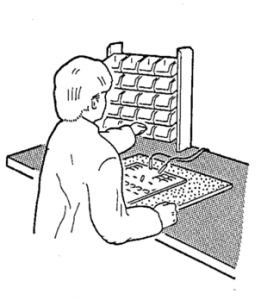

2. How to handle products in EPA areas

3. It is essential to put the groups back in the provided container

4. Components or assemblies must never be transported without the necessary protections

It is therefore necessary to use the containers to transport components and groups, for manual transports it will be sufficient to protect the groups and sticks of components with antistatic bags.

5. Rules to be observed in the repair and diagnostics phases of the products:

-

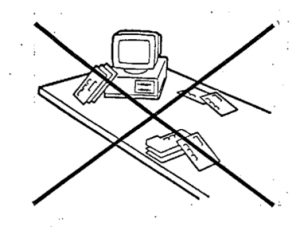

In case of powered product, it must be placed on a specific tool to avoid problems deriving from electric overstress, we recommend that the product must not be powered on surfaces that do not comply with the specifications.

-

Devices must not be removed from the circuits without first checking that the supply voltage is disconnected

- Signals must not be applied to the inputs while the supply voltage is turned off.

- You must use a special soldering iron at low voltage and controlled temperature (low voltage to avoid any dispersion of energy on the components, at controlled temperature to avoid excessive heat source on the components).

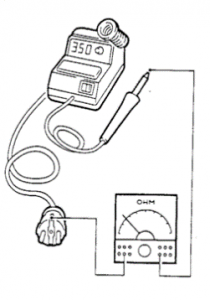

6. Precautions to be used for correct use of the soldering iron:

Avoid leaving the soldering iron on during rest or night hours, because overheating causes breakages and therefore incorrect temperature control. (+ -)

Periodically check the grounding of the soldering iron tip with a tester. The test is performed between the tip of the soldering iron and the earthing tab of the power plug.

If there is no continuity between the two points, the soldering iron tip must be cleaned with an iron brush. If no results are obtained, immediately discard the soldering iron.

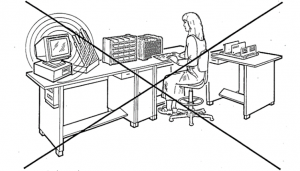

7. It is forbidden to use radio equipment:

Radio equipment emits noise that can cause component damage.

8. Watch out for video terminals

Components, packages of components or groups must be kept away from video terminals or electrified equipment to avoid the influence of variable electrical disturbances harmful to sensitive devices.

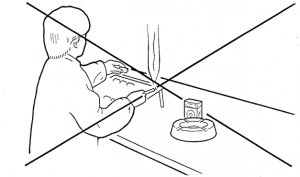

9. Smoking is strictly forbidden in workplaces equipped for antistatic protection

The carbon monoxide that smoke generates causes oxidation of the groups contacts. When removing this oxidation, the rubbing movement (especially with unsuitable tools, e.g. brushes) produces static electricity which is due to a triboelectric effect.

Come and discover Gref, our esd chair line.